We're always looking for ways to improve the sustainability, minimise ecological harm and maximise ethical standards.

This is where we're up to so far:

Delivery:

We use the excellent shipping service 'Sendle' which provides carbon neutral delivery.

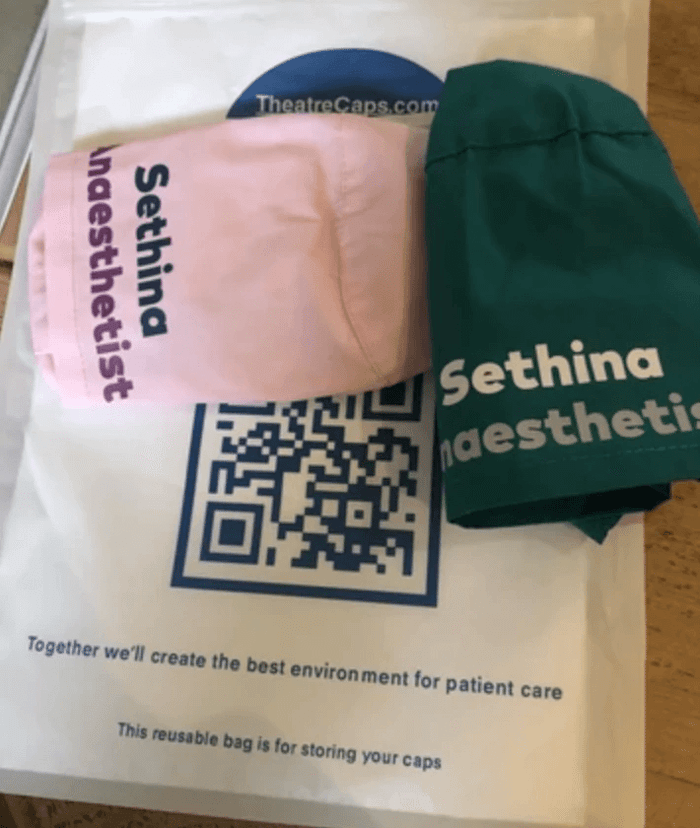

Our caps are provided in reusable bags which are designed or the co-purpose of both mailing the caps and storing clean caps in going forward.

Reusable TheatreCaps:

A 20 operating theatre hospital using disposable caps will discard a staggering 100,000 caps every year. These caps are made from viscose - a substance whose production is particularly harmful to the environment which has an impact on sustainability.

Cap Manufacturer:

The TheatreCap medical manufacturer is a 6 Star Manufacturer who goes above and beyond with ethical and sustainable practices. Wastage is a huge issue and we ensure there is no fabric or dying waste in line with the latest and highest certification levels. We go so far to ensure the fabrics are dyed with the latest of technology which ensures less water and chemicals are used to make our fabrics and garments. The factory holds a GOTS certification as well as all the other certifications required for some of the worlds largest brands compliance policies.

We ensure our manufacturers are using the highest level of technology on cutting, dying and drying. With the advances in technology even the smallest changes can avoid wastage and exceed the current environmental standards. Laser cutting for example ensures there is next to no fabrics wastage. The new dying houses and factories we employ all have the most up to date technology to ensure we reduce wastage from the older style and more traditional methods of fabric dying. The new digital print and dying technology uses a lot less natural commodities including the most valuable being water. Rinsing and drainage is refiltered and water is reused throughout the process. The wastage of water is reduced by over 80%. Wastage is now treated in our own treatment facility. The water once processed is so clean we are able to farm fish. This ensures our entire wastage treatment facility process is not only sustainable and above world wide standards but also ethical and 100% environmentally friendly.

Print Ink:

The print ink we use on the caps ECO-SOL MAX contains no harmful volatile organic compounds:

We are always looking to improve the quality of our service and are most welcome to any suggestions for change.

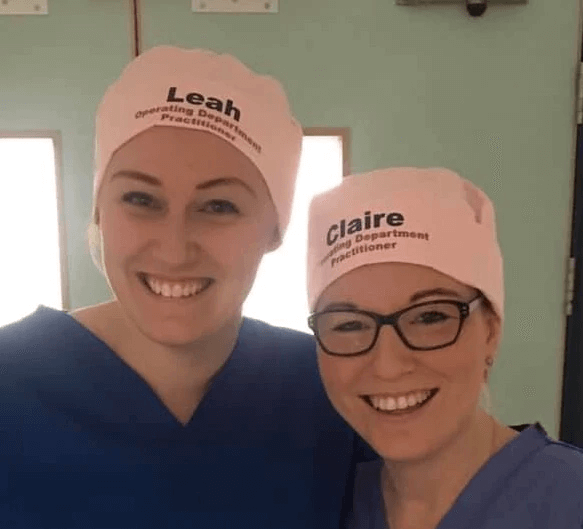

If you would like to purchase name and role personalised TheatreCaps please check out our website TheatreCaps.com. All profits from the sale of our caps go towards supporting other patient safety initiatives.